- Identification

- Properties

- Safety Data

- Specifications & Other Information

- Links

- Quick Inquiry

Identification

CAS Number

9011-06-7

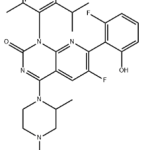

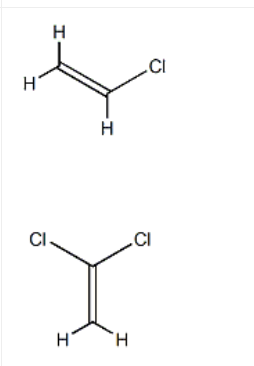

Name

vinyl chloride-co-vinylidene chloride

Synonyms

1,1-dichloro-ethylenpolymerwithchloroethylene;breon202;breoncs100/30;chloroethylene-1,1-dichloroethylenepolymer;daran;darancr6795h;dow874;dowlatex874

Molecular Formula

C4H5Cl3

Molecular Weight

159.4415

Properties

Appearance

Milky white emulsion

Safety Data

Symbol

Signal Word

Warning

WGK Germany

3

MSDS Download

Specifications and Other Information of Our

Identification Methods

HNMR, HPLC

Content

≥40%

Surface Tension mn/m

≤40

Unreacted Monomer

≤2.0%

Calcium Chloride Yield

≤10%

Intrinsic Viscosity(Ubbelohde 20°c)

0.3-0.5

Shelf Life

half of a year

Storage

Store at room temperature, sealed and away from light

Known Application

Vinyl chloride-co-vinylidene chloride is widely used in anti-seepage engineering and formulated into coatings for various purposes, such as moisture-proof coatings, anti-mildew coatings, fire-resistant coatings, floor coatings, concrete curing liquid, polymerized cement mortar, etc.

Moisture-proof coating : used in underground caverns, which can keep the relative humidity in the warehouse below 70% all the year round.

Floor paint : use emulsion to prepare 206 varnish paint and brush it on the polyvinyl formal cement coating, which is bright, wear-resistant and highly decorative, and can be widely used in civil and industrial building floors.

Polymerized cement mortar : The emulsion is added to cement and yellow sand according to the formula to prepare polymerized cement mortar with high bonding strength and water seepage resistance up to 15KG/CM2.

Concrete curing liquid : LP-37 concrete curing liquid prepared with emulsion, sprayed on the concrete surface after pouring and tamping, can replace the traditional straw bale watering and curing, the effect is good, and the price is only 1/3 of the straw bale method.

Anti-mildew coating : LP water-based anti-mold coating has a mildew-resistant performance of “0 grade”, strong washing resistance, up to 300 times, and water resistance, acid and alkali resistance. It is an ideal water-based anti-mold coating. It is suitable for interior wall coatings in light industry, food, aquatic products, tobacco and alcohol, etc. which are prone to mildew damage.

General View of Documents

Links

This product is developed by our R&D company Warshel Chemical Ltd (https://www.warshel.com/).

Quick Inquiry

Fill out our inquiry form and one of our experts will be in touch with you shortly.