The Critical Role of Anion Exchange Membranes (AEMs) in Hydrogen Energy

Anion Exchange Membranes (AEMs) are emerging as a cornerstone technology in the hydrogen energy sector, playing a pivotal role in the efficient generation, storage, and utilization of hydrogen as a clean energy carrier. These specialized membranes are engineered to facilitate the selective transport of anions, such as hydroxide ions (OH-), while impeding the passage of cations, thereby enabling key electrochemical processes to occur with high selectivity and efficiency.

In the context of hydrogen production, AEMs are integral to the operation of electrolyzers that employ water electrolysis to split water molecules into hydrogen and oxygen gases. The AEMs allow for the smooth passage of hydroxide ions from the cathode to the anode, effectively separating the gases and preventing recombination. This separation is crucial for achieving high purity hydrogen, which is essential for fuel cell applications and other hydrogen-based energy systems.

Furthermore, AEMs are utilized in fuel cells, particularly in alkaline fuel cells (AFCs), where they serve as a medium for hydroxide ions to travel from the cathode to the anode. This ion transport is vital for the electrochemical reaction that combines hydrogen with oxygen to produce water, electricity, and heat. The efficiency of this reaction is significantly enhanced by the AEM’s ability to conduct ions while maintaining a barrier to gas crossover, which can lead to reduced performance and efficiency.

The advantages of AEMs in hydrogen energy applications are manifold. They offer the potential for lower-cost materials compared to their proton exchange membrane (PEM) counterparts, as they can operate effectively with non-precious metal catalysts. Additionally, AEMs operate at higher pH levels, which can lead to reduced corrosion issues and longer membrane life. Their ability to work under less acidic conditions also opens up the possibility of using a wider range of materials for components, further reducing costs and expanding the technology’s accessibility.

As the world increasingly turns to hydrogen as a sustainable and zero-emission energy source, the development of high-performance AEMs is becoming more critical. Advances in membrane chemistry, durability, and ion conductivity are expected to propel the hydrogen economy forward, making AEMs a key enabler in the transition to a cleaner energy future. With ongoing research and innovation, AEMs are set to play a vital role in harnessing the full potential of hydrogen energy, providing a pathway to a greener and more sustainable world.

The realm of anion exchange membranes (AEMs) is witnessing a significant transformation, thanks to the continuous evolution of monomers, polymers, and the membranes themselves. AEMs are pivotal in a variety of applications, ranging from hydrogen production through water electrolysis to their use in fuel cells. The performance of AEMs is intrinsically linked to the properties of the monomers and polymers from which they are crafted. In this context, the emergence of Polyberg technology stands out, offering substantial advantages in the development of AEMs.

Monomers for AEMs

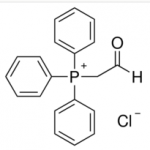

The journey of AEMs begins with the selection of appropriate monomers. These monomers must possess functional groups capable of undergoing ion exchange, typically involving quaternary ammonium, phosphonium, or imidazolium groups. The choice of monomer directly impacts the ion exchange capacity (IEC) and the stability of the resulting polymer.

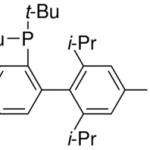

Polyberg technology leverages advanced monomers that are designed to enhance the chemical stability of the AEMs, particularly in alkaline environments, which are notoriously challenging due to the degradation of traditional quaternary ammonium groups. These advanced monomers include:

- Quaternary Ammonium Compounds: Traditional choices like tetramethylammonium (TMA) and benzyltrimethylammonium (BTMA) are common, but they often suffer from degradation in strong alkaline environments. Polyberg employs modified quaternary ammonium compounds that include sterically hindered groups to protect the ammonium functionality from nucleophilic attack.

- Phosphonium-Based Monomers: These monomers offer enhanced chemical stability over ammonium-based monomers. The robust nature of phosphonium groups provides AEMs with greater resistance to alkaline degradation, although they may come with trade-offs in terms of slightly lower ionic conductivity.

- Imidazolium Derivatives: Imidazolium-based monomers are known for their excellent ionic conductivity and stability. Polyberg incorporates substituted imidazolium compounds to improve both the IEC and the alkaline stability of the resulting membranes.

- Benzimidazolium and Polybenzimidazole (PBI): These monomers and polymers are highly stable in alkaline environments and offer a good balance between conductivity and durability. Polyberg’s technology enhances these materials further by introducing side-chain modifications that increase the IEC without compromising the mechanical properties.

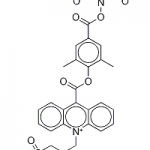

- Functionalized Aromatic Monomers: These include various aromatic rings functionalized with ion-exchange groups. Aromatic structures provide a stable backbone, and when combined with appropriate functional groups, they contribute to high-performance AEMs.

Polymers for AEMs

Polymers derived from these monomers must exhibit a fine balance between hydrophobic and hydrophilic domains to facilitate ion transport while maintaining structural integrity. Polyberg polymers excel in this regard, offering a robust backbone that ensures mechanical strength and durability.

- Quaternary Ammonium Functionalized Polymers: Polymers such as quaternary ammonium poly(arylene ether sulfone) (QAPES) and quaternary ammonium poly(phenylene oxide) (QAPPO) are tailored for high IEC and stability. Polyberg’s innovation lies in the precise control of the degree of quaternization and cross-linking to optimize the balance between conductivity and mechanical integrity.

- Cross-Linked Polyolefins: By introducing cross-linking agents, Polyberg enhances the mechanical properties and reduces the swelling of polyolefin-based AEMs. Cross-linked polyethylene (PE) and polypropylene (PP) backbones are common, providing toughness and durability.

- Imidazolium Functionalized Polymers: Poly(imidazolium styrene) and its derivatives are designed for high ionic conductivity and chemical stability. Polyberg’s unique synthesis methods ensure these polymers maintain their performance under harsh conditions, with minimal degradation over time.

- Polybenzimidazole (PBI) and Its Derivatives: PBIs are inherently stable polymers used in high-temperature applications. Polyberg’s modifications to PBI, such as the introduction of quaternary ammonium or phosphonium groups, create AEMs with exceptional performance metrics in terms of both conductivity and mechanical strength.

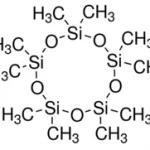

- Advanced Composite Polymers: Polyberg also integrates inorganic fillers like silica or titania into the polymer matrix to enhance the thermal and mechanical properties of the AEMs. These composites exhibit lower gas permeability and improved durability under operational stresses.

Anion Exchange Membranes

The AEMs crafted from Polyberg polymers demonstrate superior ion conductivity, a critical parameter for energy efficiency in electrochemical applications. The membranes showcase low electrical resistance, which translates to lower energy consumption and higher efficiency in hydrogen production. Furthermore, Polyberg AEMs exhibit reduced gas crossover, a common issue that leads to reduced performance and safety concerns in fuel cells.

Advantages of Polyberg Technology

- Enhanced Chemical Stability: Polyberg AEMs resist degradation in alkaline conditions, ensuring a longer operational life and reducing the frequency of membrane replacement.

- Improved Mechanical Properties: The structural design of Polyberg polymers provides AEMs with the necessary toughness to withstand the rigors of use in dynamic environments.

- High Ion Conductivity: Polyberg AEMs maintain excellent ion transport rates, which is essential for achieving high efficiency in electrochemical processes.

- Reduced Gas Crossover: The advanced structure of Polyberg AEMs minimizes the permeability of gases, enhancing the safety and efficiency of fuel cells.

- Given China’s leading global advantages in policies, technology development, and industrial chains in the field of hydrogen energy research, as well as its vast market potential, Polyberg is actively collaborating with partners in China through Watson. This includes cooperation with institutions such as the Polymer Research Institute at Sichuan University, to jointly advance the development of hydrogen energy-related monomers, polymers, and anion exchange membranes.

Cost-Effectiveness: By improving the longevity and performance of AEMs, Polyberg technology contributes to a reduction in overall operational costs, making it an economically attractive option for industrial applications.

The development of AEMs is a complex interplay of monomer selection, polymer chemistry, and membrane engineering. Polyberg technology addresses the critical aspects of this interplay, offering AEMs that stand out in terms of stability, performance, and cost-efficiency. As the demand for clean energy solutions grows, the advancements provided by Polyberg technology will play a significant role in the widespread adoption of hydrogen energy systems.

If you are interested in Polyberg’s AEMs or upstream monomers and polymers, or you are looking to invest in this field, please contact us by sending us email or visit Polyberg Official Website for more details.

![Structure of tetrakis[(epoxycyclohexyl)ethyl]tetramethylcyclotetrasiloxane CAS 121225-98-7](https://www.watson-int.com/wp-content/uploads/2024/06/Structure-of-tetrakisepoxycyclohexylethyltetramethylcyclotetrasiloxane-CAS-121225-98-7-150x150.png)